In a world with same-day shipping and five-minutes-or-less delivery, there is a high demand for streamlining processes in an efficient and cost-effective manner. Through the use of our Concept to Production capabilities, NuWaves RF Solutions is able to simplify product creation and produce it entirely in-house—saving our customers time, energy, and money. Check out behind the scenes of our one-stop-shop system and how it outputs quality, field-ready modules and equipment.

Step 1: Concept

Each new challenge invigorates us to dive deeper into understanding and innovating within the world of RF and microwave engineering. Whether you have a problem that needs to be solved, or an opportunity that needs to be developed, we are prepared to maximize your RF capability and readiness. For fully or partially developed concepts, our experienced engineers can work with your team to evolve an idea to a full solution that fits your needs. Not even sure where to start? Through in-depth research and inventive thinking, NuWaves can create a turn-key solution just for you. One of the key benefits of this stage is due to our fully in-house manufacturing system, we are able to cultivate the concept with production in mind.

Step 2: Design

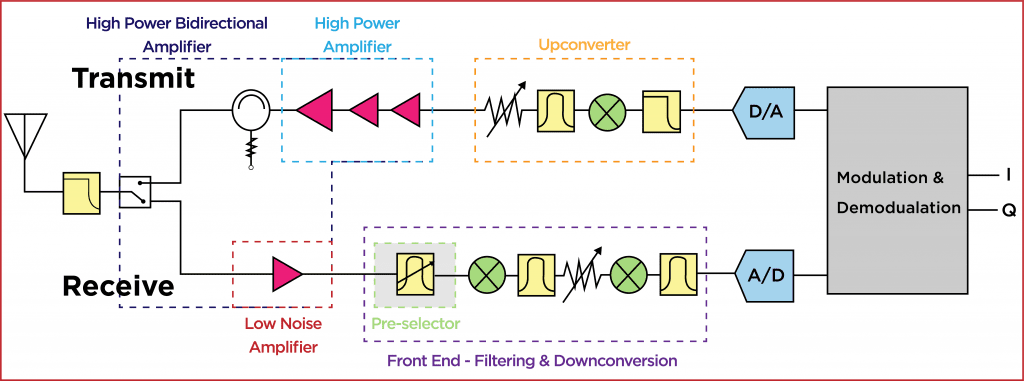

With each project, we keep the idea of “design for manufacturability” in mind. At this stage in the process, our highly skilled team leverages our experience in military and defense design to develop a module that meets the demands of its environment. We offer a full suite of system and sub-system design, synthesis, and analysis services. NuWaves specializes in the design of power amplifiers, transmitters, receivers and front-ends, high power frequency converters and signal sources, and systems/sub-systems. We keep you updated throughout the entire design process and ensure our planned solutions are up to quality standards and within your budget.

Step 3: Qualification

A sub-phase within the design phase includes product qualification. NuWaves frequently designs and tests to MIL-STD documents and we quickly and cost effectively meet stringent system level qualification requirements. We have an in-house anechoic chamber, vibration/shock table, and temperature and humidity chambers to test a wide range of EMI/EMC and environmental conditions for military applications. Conducted fully in-house, we receive the results of tests in real time, which results in immediate problem solving and design adjustments—saving time and eliminating outsourcing costs.

Step 4: Production

Over 3,000 square feet of our facilities are dedicated to manufacturing and production with state-of-the-art equipment. NuWaves is certified to AS 9100:2016 Rev D and ISO 9001:2015 standards to guarantee that your custom solution is high-quality and can endure rigorous use. Our capability to produce in-house provides you with greater control over the outputs (considering both product quality and design changes/updates) and allows for shorter lead times. We produce and design for defense, military, and high-end commercial markets.