Highly Specialized Contract Manufacturing of Circuit Card Assembly and Electronic Mechanical Assembly

Contact usCIRCUIT CARD ASSEMBLY AND TEST SERVICE

NuWaves has invested significant resources towards in-house capabilities to improve prototyping, production, testing and more. These services enable us to better serve our customers with quick-turn projects, high quality production builds, and thorough hardware performance evaluation.

AT A GLANCE

- AS9100D Certified

- Circuit Card Assembly

- High Reliability Products

- High Volume Throughput

- Mechanical Assembly

- In-House Machine Shop

- DFAR Compliant

- Engineering Support Team

- Low Rate Initial Production (LRIP)

- Flexible

- Quick Reaction

- IPC Certified Team

- ITAR Compliant

- Quick-Turn Prototyping

- Risk Mitigation

- Testing of Electronic Assemblies

- Wiring Harness Assembly

- Rapid Prototyping

Our Markets

WHERE WE FIT IN

Our contract manufacturing team has the skills and expertise to fabricate, test, and deliver high quality products for a variety of applications and design maturity levels. From start to finish, we treat your products like our own in order to support and deliver on time and on budget

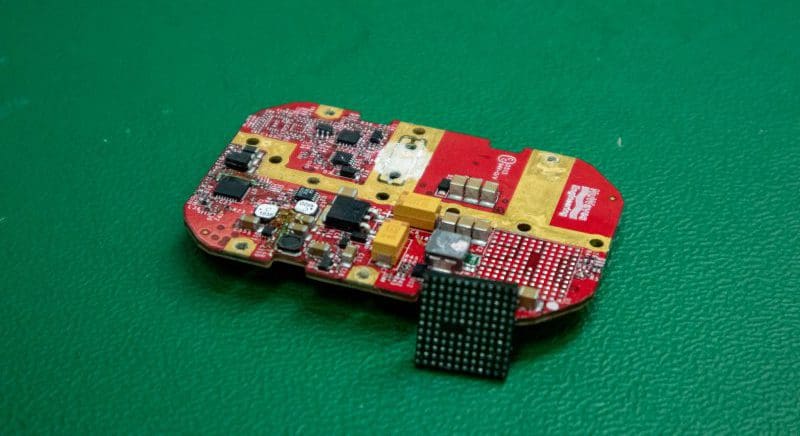

CIRCUIT CARD & CABLE/WIRING HARNESS ASSEMBLY

NuWaves manufactures ultra high density circuit card assemblies for use in high reliability military and commercial systems. We build a wide variety of circuit card assemblies, including RF power amplifiers, frequency converters, filters, digital I/O, power supplies, etc. We provide the end-user with defect free products for peace of mind. We additionally build custom cable assemblies for routing signals and power.

Capabilities

- Surface Mount Components (Down to 0201 Size)

- Multi-Layer and Single-Layer CCAs

- CCA Level Testing

- CCA Integration into Higher Level Assemblies

- BGA and LNA Installlation

High Power Signal Wiring Harness Production of Digital I/O CCA

LGA/BGA Installation and Rework Capability Conformal Coating Capabilities

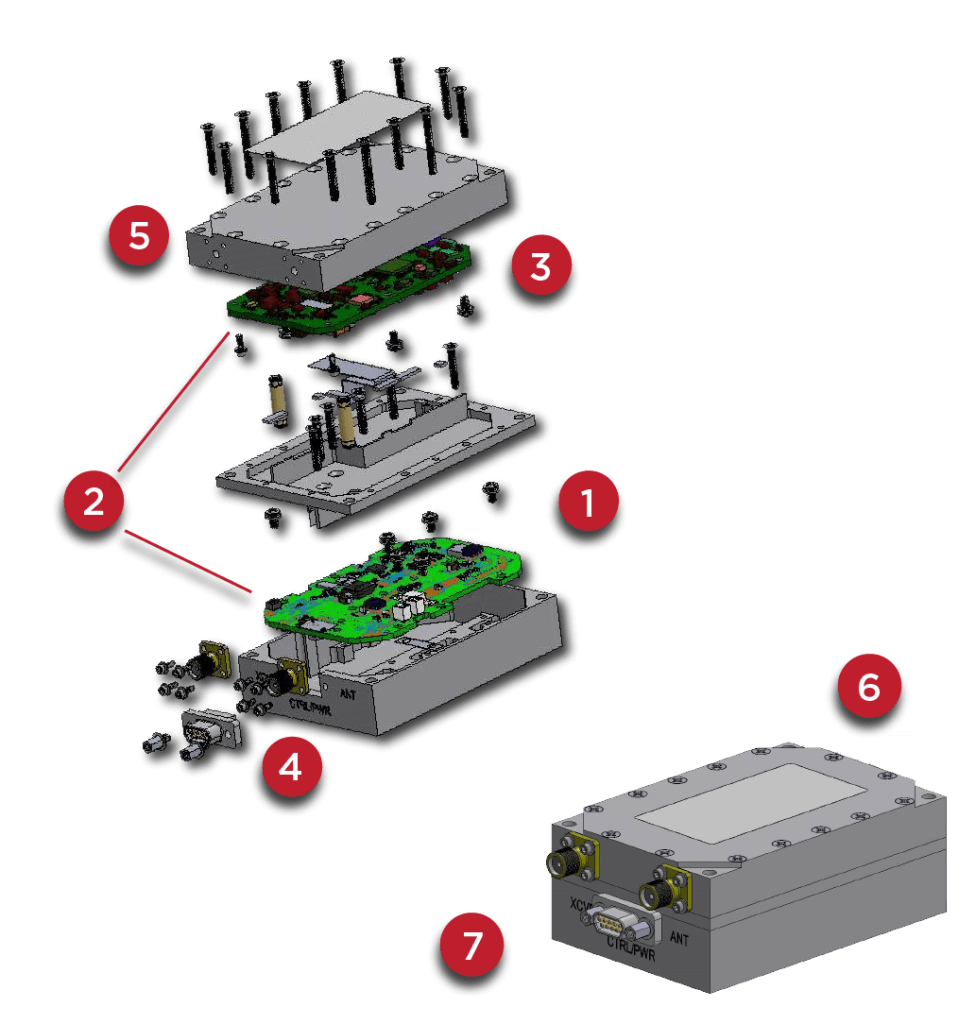

TOP LEVEL AND MECHANICAL

NuWaves provides added value to the contract manufacturing process by providing installation and integration of circuit card assemblies and sub-modules into higher level assemblies. These can range from small to large. Our internal machine shop allows for quick-turn contract manufacturing and provides a one-stop-shop from CCA to top level integration.

Capabilities

- Top Level Assembly

- Top Level Integration

- Machining of Electrical Housing

- Quick-Turn Production

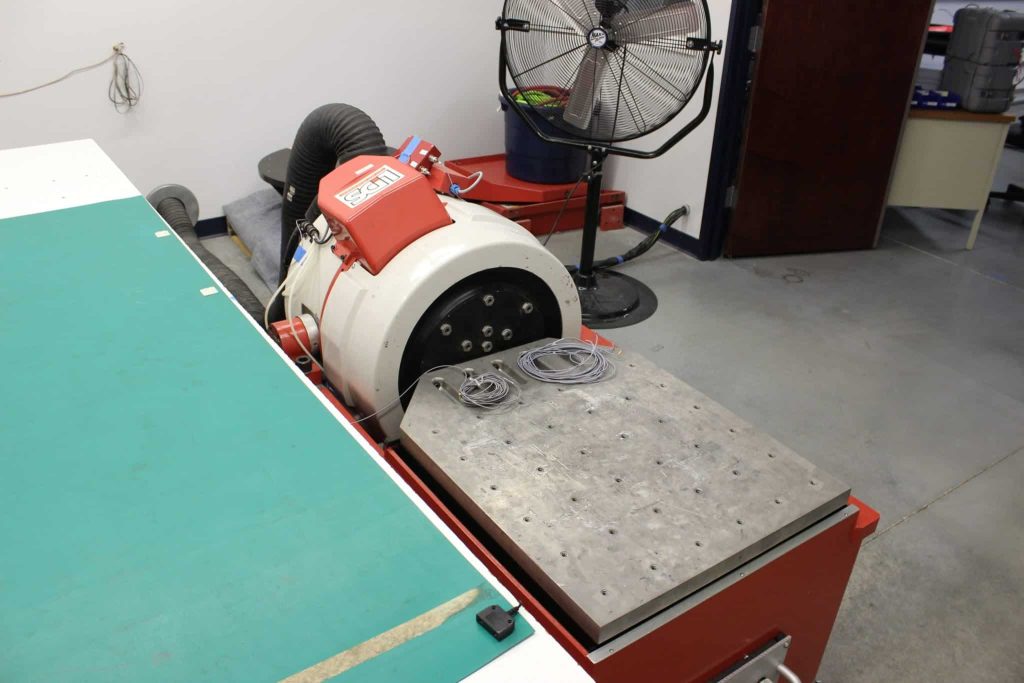

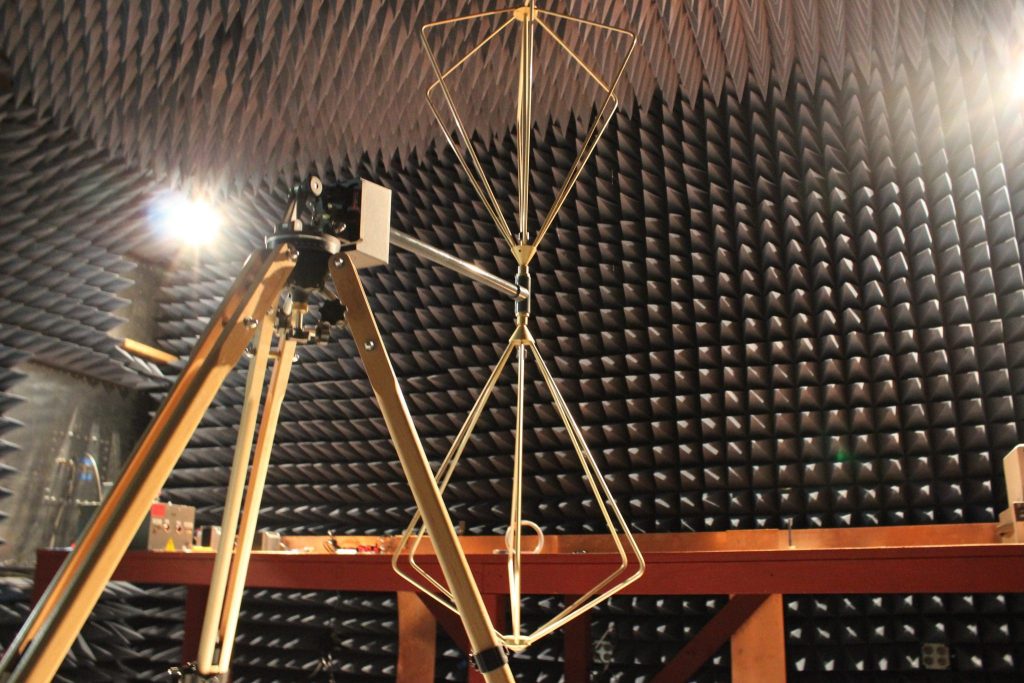

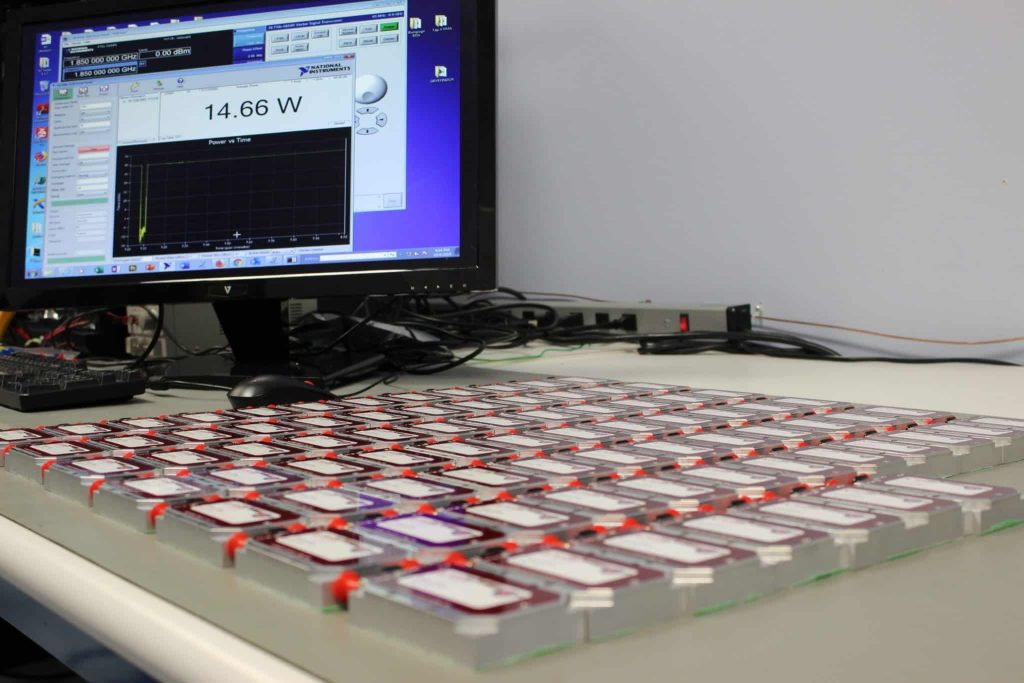

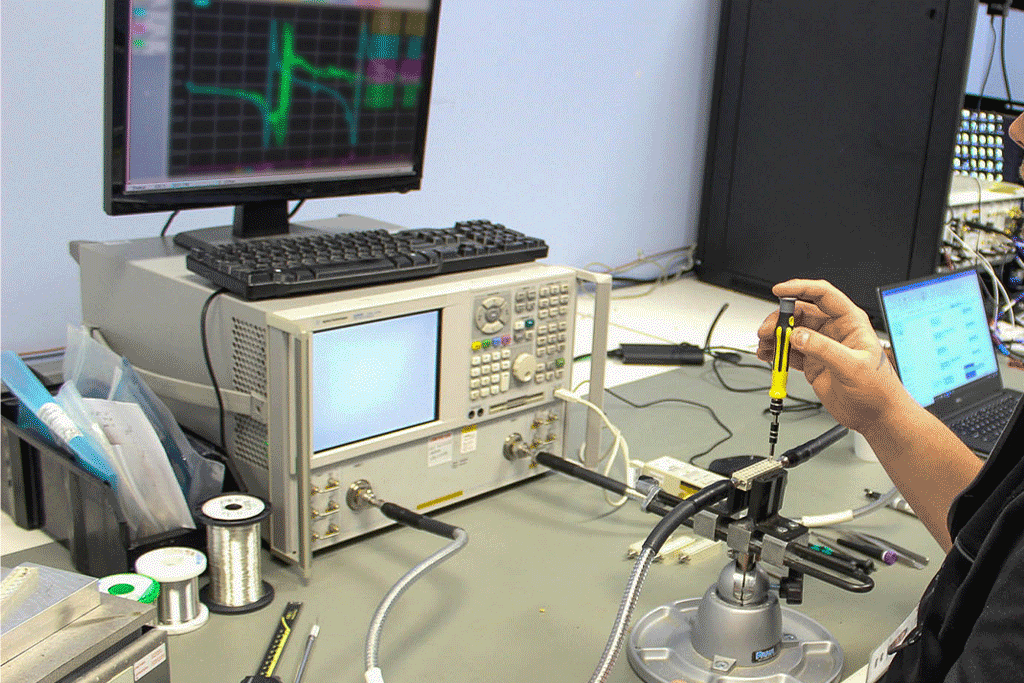

TEST CAPABILITIES

NuWaves provides testing services throughout the entire contract manufacturing process. Our highly technical team provides testing at the CCA level, component level, top level, and system level of the production process.

NuWaves captures the experience and knowledge of its design engineering personnel while exploiting the vast capabilities of its facilities to ensure that it produces quality, quick-turn, and on-time services. With a varied product base, our engineers have the knowledge to support production programs, such as product development and customer build-to-print. Our engineering department provides strategic information for PCB and mechanical assembly during, and at all phases of production and testing. Additionally, we offer the ability to troubleshoot issues and work effectively with your team to develop solutions.

Capabilities

- Immersion

- Altitude/Leak

- Temperature

- Thermal Shock

- Humidity

- RF Test Screen Room

- Environmental Stress Testing

- Circuit Card Assembly Testing

- Electrical Design Testing

- Verification and Validation Testing

- MIL-STD Testing

- High-Level Module and System Testing

- Production Acceptance Testing

- Automated Testing

- Continuity Checks

- Troubleshooting