Author: Tim Wurth, Chief Technical Officer

Date: June 4th, 2025

These are exciting times for electronic equipment manufacturers. A drastic increase in space missions, together with a push to lower the cost and time to launch, has created opportunities for traditional manufacturers of electronic modules to have their Commercial-Off-The-Shelf (COTS) hardware used in space. Let us consider the issues and constraints of using COTS electronic modules for space missions.

Over the last ten years, the world has witnessed a historic surge in space launches and missions, marking the dawn of a new space age. What was once the domain of superpower governments has become a dynamic, fast-moving sector that includes commercial ventures, emerging space nations, mega-constellation operators, and private citizens. The volume, diversity, and ambition of missions launched in the 2020s surpass anything seen before. This exponential increase in objects placed into space is shown in Figure 1. The United States mainly leads the surge.

Figure 1: Exponential Increase in Space Hardware over the last 10 years

Figure 1: Exponential Increase in Space Hardware over the last 10 years

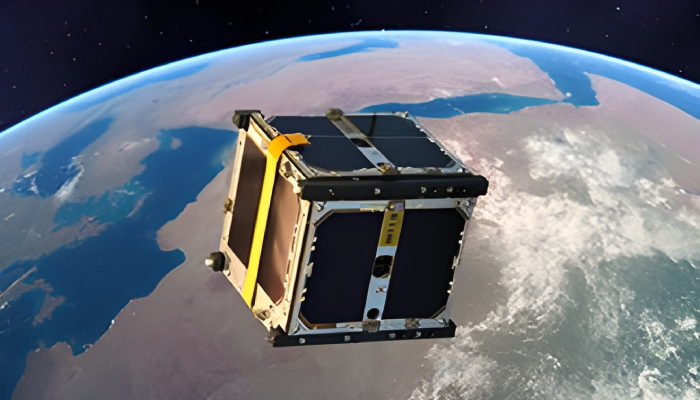

New companies have been founded to address these recent space opportunities. These opportunities are largely for small satellite constellations in low-earth orbit (LEO) and for CubeSat platforms, which often have shorter mission durations, lower mission criticality, and limited budgets. Consequently, the space industry has seen a dramatic rise in adopting COTS modules due to increasing pressures to reduce costs and accelerate development timelines. The use of readily available, high-performance COTS electronics has become both attractive and, in many cases, necessary. However, space remains one of the harshest environments for electronics, and the use of non-space-qualified components introduces risks that must be managed through rigorous engineering and quality assurance protocols. Key to addressing the risk of using COTS hardware is understanding the space environment and duration for each specific space mission.

COTS hardware offers promising advantages in cost, availability, and performance; however, its use in space presents formidable challenges. These include exposure to the space radiation environment, thermal cycling, vacuum outgassing, and mechanical shock and vibration. The fundamental issue is that COTS modules were not designed to operate in a space environment.

Space presents a set of extreme conditions that severely test the durability and reliability of electronic modules. These include:

- Radiation: Including total ionizing dose (TID), displacement damage (DD), and single-event effects (SEE).

- Thermal extremes: Components may face cycles from -150°C to +125°C, especially in low Earth orbit (LEO).

- Vacuum conditions: Which can lead to outgassing of materials and electrical arcing.

- Mechanical stress: Vibration and shock during launch must be withstood by all spacecraft hardware.

- These environmental conditions can cause degradation or catastrophic failure in inadequately hardened or tested components.

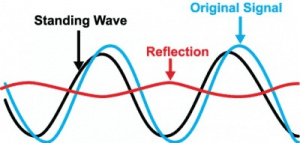

Radiation presents one of the most critical challenges for COTS electronic modules in space. Radiation can affect electronics through:

- Total Ionizing Dose (TID): Gradual accumulation of charge in oxides leading to threshold shifts and leakage currents.

- Single-Event Effects (SEEs): Disruptions caused by single high-energy particles, including single-event upset (SEU), latch-up (SEL), and gate rupture.

- Displacement Damage (DD): Structural defects in semiconductor crystals affecting performance.

COTS modules are particularly susceptible to these radiation effects as the internal electronic components were fabricated using smaller geometries and low-voltage thresholds. These are perfectly acceptable for terrestrial applications but not optimized for radiation tolerance in a space environment.

Concerns about using COTS modules include possible failure due to radiation, a lack of process control, limited traceability, insufficient testing, and packaging materials not suitable for vacuum or thermal extremes. Additionally, die shrinks and process changes by manufacturers can introduce unknown reliability risks. COTS modules must be carefully assessed and verified before space qualification. Key challenges include:

- No radiation test data.

- Limited environmental test data.

- Unknown infant mortality rates.

- Plastic encapsulation issues.

- Lack of upscreening or lot screening.

Mitigation strategies are used to address these risks. Radiation testing for tolerance to TID and SEE using ground-based facilities. Radiation Hardness Assurance (RHA) is a process of verifying that an electronic component or system can operate reliably in its intended radiation environment. For COTS modules, the RHA process includes:

- Environment definition: Analysis of radiation levels for a given mission profile.

- Test-to-failure analysis: Determining the module’s margins.

- Shielding: Employing aluminum or composite materials to reduce flux.

- Part acceptance: Based on heritage data, vendor claims, and past mission usage.

Another common risk mitigation strategy is component and module burn-in and screening to eliminate early-life failures. Design derating, where the COTS module is operated below rated limits, is also utilized. Lot traceability is used to ensure uniformity and traceable quality.

Organizations like NASA and the European Space Agency (ESA) have formal processes for including COTS through tailored screening and qualification programs. Below are some references to help in the process of using COTS modules for space missions.

- COTS Components in Spacecraft Systems: Understanding the Risk [COTS.pdf]

- ESA ECSS-Q-ST-60-15C – Radiation Hardness Assurance [ECSS-Q-ST-60-15C – Radiation hardness assurance – EEE components (1 October 2012) | European Cooperation for Space Standardization]

- NASA/GSFC Radiation Effects and Analysis [Radiation Effects and Analysis | Goddard Engineering and Technology Directorate]

- ECSS-Q-ST-60-13C – Use of COTS in Space Applications [ECSS-Q-ST-60-13C Rev.2]

- NASA-STD-8739.10 – EEE Parts Assurance Standard [nasa-std-873910.pdf]

- ESA COTS Workshop Proceedings, 2021 Utilization of COTS in ESA Missions